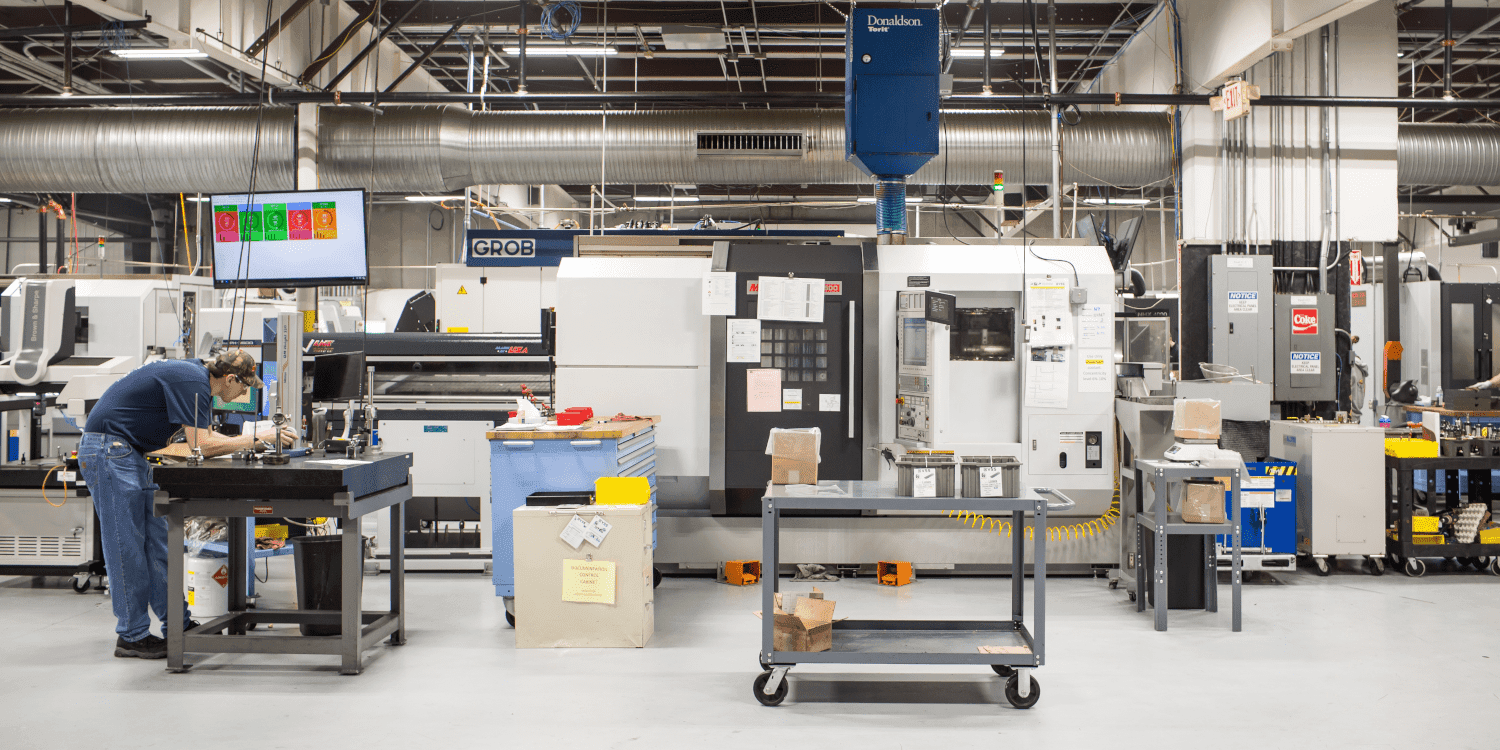

Ways to Improve Metal Fabrication Machine Shop Revenue

If you think your machine shop is already efficient, think again. Big businesses today constantly invest huge sums to make improvements to their production methods to increase their productivity and profitability, while also being environmentally friendly. To achieve this most machine shops, focus on perfecting three factors that contribute to increasing efficiency: equipment, employees, and processes.

Practice Lean Manufacturing

Lean manufacturing is the methodology that focuses on reducing waste, while simultaneously increasing the output of a production system by implementing a set of governing principles.

Key Principles of Lean Manufacturing:

Workflow – Lean manufacturing ensures a steady workflow of the machine shop by simplifying procedures, optimizing the workspace, and delegating work appropriately.

Company Culture – As Aneel Bhusri once said “Happy employees build great products…,” Lean manufacturing practices ensure the workspaces are safe, healthy, and conducive to productivity while ensuring that the employees are empowered and treated humanely.

Customer Value in Lean Manufacturing – Focuses on optimizing daily operations to meet the needs of the customers.

Continuous Improvement – Stresses the continuous improvements in processes to reduce waste, eliminate costs, and increase productivity.

Just-in-time – A lean manufacturing technique that emphasizes producing meet customer orders without making excess inventory.

Value Stream Mapping – A lean manufacturing tool used to analyze and improve the flow of material and information through the production system.

Standardization – Involves the standardization of processes and procedures for all aspects of production. [1]

Sticking to a Realistic Timeline

To ensure productivity in the shop it is necessary to create strict, easy, and efficient timelines. Falling behind on delivery or delay in production can cause a massive dent in a company’s reputation, and, in turn, can lead to a loss of orders and customers. As a reason, it is not only imperative to create realistic goals and timelines but also to effectively communicate those goals and timelines with employees to ensure maximum success.

Automation and Updating processes

Any issues causing delays and bottlenecks in production must be rectified immediately to ensure the smooth flow of output. For instance, optimizing the workspace by reorganizing equipment or reassigning employees to different machines in the shop. Time is money for businesses, so it is essential to rearrange the workspace to reduce delays, sometimes it should also be done to reduce or limit the movement of the workers to speed up production. For instance, if employees must go from one end of the machine shop to the other to utilize a certain machine, relocate the equipment in question. Similarly, budget changes, upgrading machinery, or software can improve productivity. Upgrading processes results in better efficiency in production, improved competitive advantage, greater customer and employee compliance, improved safety, and increased innovation.

Automation is a requisite in today’s day and age to satisfy the growing demands of customers and to be competitive in the market. Robots and other advanced tools speed up the production processes as they can work non-stop with greater accuracy ensuring a good quality finished product. Automated robots can be designed to fit various aspects of the production system, such as stocking products in the warehouse, packaging, or assembling.[2]

Maintain your equipment

Equipment failures can never be good news for a business. Equipment delays can cause unnecessary delays or stall production entirely, which could lead to massive losses for the company. For that reason, it is a must that the workers or maintenance team ensure the regular upkeep of the machinery. Companies must use preventive measures to avoid such mishaps and safeguard the lifespan of the machines. Preventive maintenance entails routinely planned maintenance procedures intended to avoid equipment failure and maintain machinery in excellent operating order.

Invest in your workers

Investing in your employees can only be good for a business. Well-trained and skilled workers will likely result in increased productivity as they are less prone to make mistakes and will be able to navigate through their work responsibilities with merit.

Some tips to help your staff work better:

-

Provide low-skilled workers with educational and preparational material to help them work on the job and continue to expand their skillsets and experience.

-

Offer quarter or annual reviews to touch base on individual performances and company expectations, while also providing constructive criticism to improve the quality of their work.

-

A good work culture and work environment guarantees increased employee retention and improved productivity of the workers.[3]

Stay Organized

Good organization of resources results in less confusion, lower wasted hours, and an increased rate of production. To increase production, you must arrange your metal fabrication equipment properly. Additionally, it is necessary to name and store tools, supplies, and other goods correctly.[4]

Get a Supplier Management System

The consolidation of multiple vendors into a cohesive system is a beneficial facet of running a productive and profitable machine shop. Your requirement to communicate with as many vendors can be decreased by using a vendor management software solution. Additionally, it may support the development of enduring commercial ties and your greatest collaborations. [v]

[1] https://www.princemanufacturing.com/nine-ways-to-increase-metal-fabrication-productivity/

[2] https://www.msuite.com/10-ways-to-improve-your-fabrication-shop/

[3] https://crayondata.ai/five-ways-to-improve-metal-fabrication-efficiency/

[4] https://www.princemanufacturing.com/nine-ways-to-increase-metal-fabrication-productivity/

[v] https://crayondata.ai/five-ways-to-improve-metal-fabrication-efficiency/